Since our parent company’s formation over 70 years ago in the United States of America, Air Products have provided innovative solutions to meet the gas requirements of our customers. In fact, Air Products pioneered many of the developments that have made industrial gas plants an integral part of modern industry. Air Products continues to strive to provide safer, more economical, and more reliable long-term supplies of industrial gas.

Today the company provides On-site Gas Generation Systems that include small membrane cabinets, packaged plants, large air separation and hydrogen/carbon monoxide/syngas plants and industrial gas pipelines. The systems are broken into two general classifications: Generated Gases and Tonnage Gases.

Generated Gases can supply:

Generated Gas Systems benefit customers not only by providing economical gas supply but also by creating environmental advantages through reduced truck deliveries. Whether you are based in a remote area, or in an urban environment, our Gas Generation Systems can be equipped with advanced telemetry and control for remote monitoring, combined with locally based engineers, available 24 hours a day, which will ensure smooth running of the equipment and give you peace of mind.

Tonnage Gases can supply:

Air Products brings benefits to its Tonnage Gases customers by providing a support network of hundreds of engineers and staff with expertise in plant operations. In addition to the support network, Air Products has on-location staff to support the smooth and reliable operation of all our plants.

In summary, whether you are a Generated Gases or Tonnage Gases customer, Air Products provides a complete range of engineering services from concept and project management, through to plant design and construction, to the installation, operation and maintenance of the units. Teams of qualified, experienced engineers and support staff are ready to make available Air Products’ expertise, providing the optimum total gas generation package to suit your needs.

Outsourcing can lower the cost of hydrogen, carbon monoxide or syngas (HyCO) to the refining or petrochemical industries. Air Products’ skills and expertise are geared towards producing HyCO products in the most cost-effective and reliable manner. Air Products internationally own and operate 35 steam reformers and partial oxidation units around the world, located in areas of high refinery and petrochemical activity such as: Rotterdam, The Netherlands; Texas and Louisiana, US Gulf coast; Los Angeles Basin, California; and Mab Tha Phut, Thailand.

Utilising this continuous operational experience, Air Products brings advantages in HyCO supply not normally available to the typical refiner or chemicals producer. Feedback and bench-marking from its own HyCO plants allows continuous improvements to be made both in initial design and in on-going optimisation, offering significant cost savings. Further cost reductions are possible by linking HyCO consumers together through a pipeline supply network with multiple plant capability.

With large capital investment expected to be required – especially in refining in the near to mid-term and with refining margins not expected to be supportive of such investment – out-sourced HyCO supply offers an effective way to minimise costs. Perhaps more significantly in today’s climate, it releases capital for other investment opportunities aimed at improving the refinery margin.

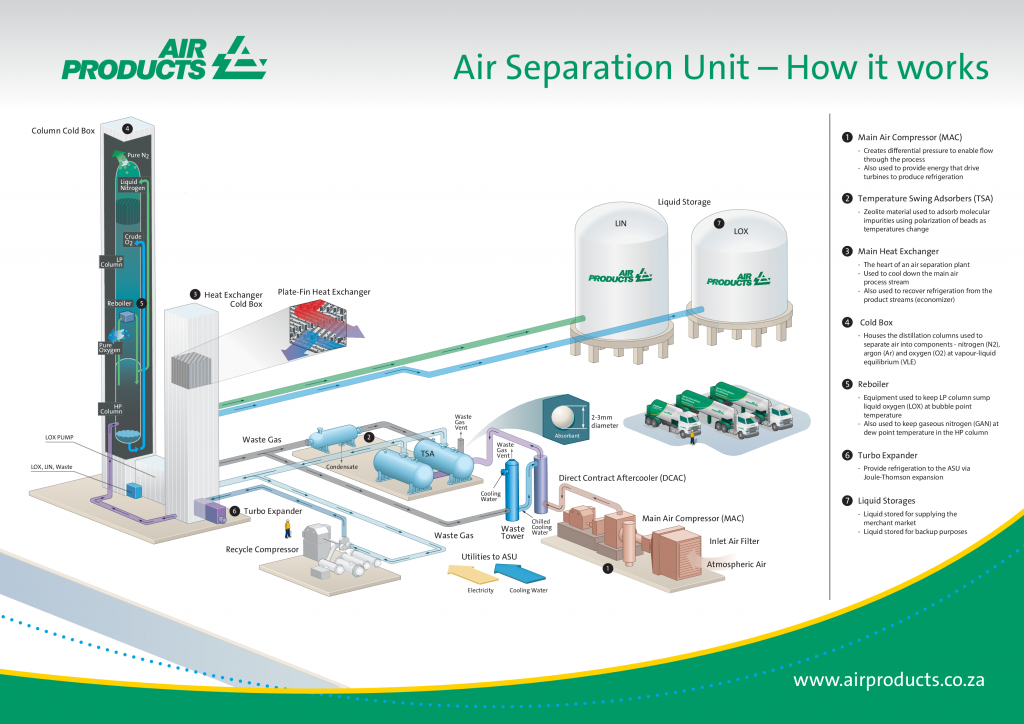

Customers who require large, or ‘tonnage’ volumes of oxygen and/or nitrogen in a continuous fashion can obtain them from an Air Products dedicated plant or pipeline. The products will commonly be produced in a cryogenic air separation plant which operates by compressing air and cooling to cryogenic temperatures under which conditions the air liquefies and can be separated by distillation.

Plants supplying up to 3000 tons per day of gaseous oxygen are available to meet the needs of the metals, glass, refining and petrochemical industries. These plants co-produce nitrogen and frequently are constructed to produce liquid oxygen and nitrogen as local back-up or for merchant export. A similar flexibility in size is available in nitrogen-only plants which find application in metals, electronics, refining, chemicals, enhanced oil recovery and natural gas dilution.

The company has developed extensive pipeline networks supplying a large number of customers in the Vanderbijlpark, Vereeniging, Sasolburg and Newcastle areas. Reliable supplies of oxygen, nitrogen, argon, hydrogen and carbon dioxide to major corporations in the steel, chemical, petrochemical and engineering industries have enabled the company to remain the leader in this supply field.